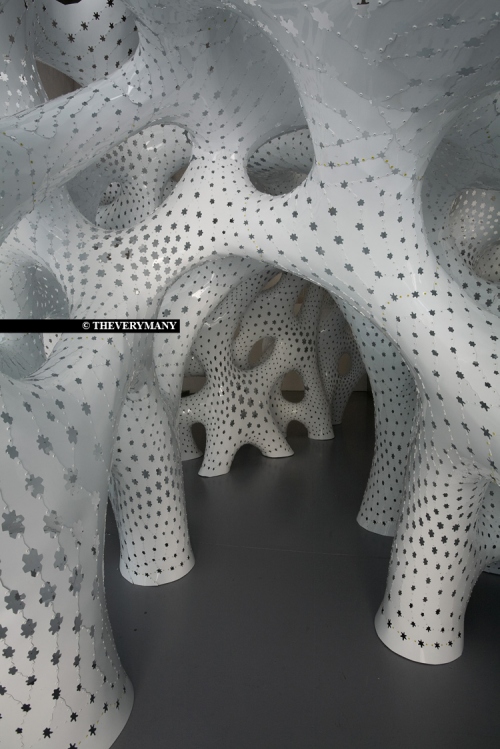

Marc Fornes – FRAC Centre, Orleans

I was pleased to be able to attend my second Tex-Fab symposium and workshops this past weekend in downtown San Antonio, just a few minutes from my home. This annual event features leaders in the digital design and fabrication field, a growing acumen among environmental designers worldwide. Tex-Fab is an organization promoting the application of technologies in industry to the production of architecture. From their website: “Within Texas there is an emerging network of companies, institutions, and individuals focusing on the exploration of parametric design and the digital production of building components. Specifically, there is a growing opportunity for collaborative exchange between the academic, technical, and professional communities by leveraging the immense resources found in some of the largest metropolitan centers across the United States.”

The event was hosted by the College of Architecture at UTSA. Workshops included 3-D computer design topics from introductory to advanced levels. Building information modeling (BIM) techniques with Autodesk’s REVIT was my focus, and we concentrated on parametric controls of geometry. We want to be able to model buildings and components, then be able to easily manipulate and control changes to study alternatives. You might think of it as a virtual row of clay models, each a variation on an idea. My hands aren’t dirty, though, and there is a stream of data available to help me compare alternatives. Everything from quantity take-offs of materials, to energy consumption data, solar radiation intensity and wind interaction can be simulated in the computer model versions of the clay.

Marc Fornes – FRAC Centre, Orleans

Marc Fornes made the keynote lecture running through the computational design journey and his “failures” over the last ten years. The point was With each successful project he has carried out there have been surprises from which he has learned. His term for what his company – THEVERYMANY™ – does is “precise indetermination…” so he is constantly open to the unexpected joys of design. The example shown is made of thousands of thin aluminum pieces precisely cut by computer numeric controlled (CNC) machining, and hand riveted together.